Driving High-Quality Growth Through Digital Transformation

_03fdc.webp)

_03fdc.webp)

How YG Group Achieved Breakthroughs in Provincial and Municipal Digitalization Programs

In recent years, digital transformation has become a national strategic priority for China’s manufacturing sector. As industries accelerate toward intelligent manufacturing and data-driven operations, enterprises with strong execution capabilities and strategic vision are gaining a clear competitive edge.

In response to these trends, YG Group has actively advanced its digital transformation roadmap. Under the strategic leadership of Group Vice President Mr. Jiang Haiquan, and supported by close cross-department collaboration, the company has achieved a series of milestone breakthroughs in intelligent manufacturing, enterprise digital governance, and policy-driven innovation.

By accurately identifying policy opportunities and systematically advancing implementation, YG Group has earned multiple provincial- and municipal-level digital transformation recognitions, while successfully securing substantial government incentives. These achievements further strengthen YG Group’s position as a leading manufacturing enterprise committed to long-term digital excellence.

Establishing a Cross-Department Digital Transformation Governance Framework

To ensure effective execution, YG Group established a dedicated task force led by the IT Department, working closely with Administration, Finance, Technology, and Corporate Communications. This structure formed a closed-loop governance model covering policy analysis, project application, technical validation, financial management, and brand communication.

As part of its long-term vision, YG Group continues to strengthen its digital transformation strategy, aligning enterprise-level systems with national and regional digitalization initiatives.

Defined Responsibilities, Coordinated Execution

-

IT Department

Leads policy interpretation, digital roadmap planning, and unified system architecture. It also coordinates digital material preparation across subsidiaries, ensuring alignment with evaluation standards. -

Administration Department

Acts as the government–enterprise liaison, maintaining smooth communication throughout application, evaluation, and verification stages. -

Finance Department

Oversees incentive fund tracking, compliance management, and reinvestment planning to ensure that subsidies directly support digital infrastructure and system upgrades. -

Technology Department

Provides validated technical outputs, system parameters, and innovation results, reinforcing the credibility of digital applications. -

Corporate Communications Department

Enhances visibility of transformation achievements through branding, media exposure, and corporate storytelling, reinforcing YG Group’s industry image.

This coordinated mechanism ensures that digital initiatives are executed efficiently, transparently, and with measurable impact.

Municipal-Level Digital Maturity Certification: Strengthening Industry Position

At the municipal level, YG Group achieved strong results in the Manufacturing Enterprise Digital Development Level Evaluation, earning authoritative certifications issued by provincial authorities.

Through continuous investment in smart manufacturing solutions, multiple subsidiaries achieved recognized digital maturity levels:

- JIANGXI YONGGUAN TECHNOLOGY DEVELOPMENT CO., LTD. – L7

- JIANGXI ZHENGUAN NEW MATERIAL CORP., LTD. – L6

- JIANGXI LIANGUAN NEW MATERIAL TECHNOLOGY CORP., LTD. – L6

Corresponding incentive funds have already been disbursed in an orderly manner.

These certifications validate YG Group’s advanced digital integration capabilities across production, management, and decision-making processes.

Provincial-Level Digital Benchmark Recognition

At the provincial level, YG Group achieved significant breakthroughs, further demonstrating its leadership in intelligent manufacturing and digital innovation.

Provincial Benchmark Projects Successfully Publicized

-

JIANGXI ZHENGUAN NEW MATERIAL CORP., LTD.—“Small Lighthouse” Digital Benchmark Project

-

JIANGXI ZHENGUAN NEW MATERIAL CORP., LTD. – Smart Factory Project

-

JIANGXI LIANGUAN NEW MATERIAL TECHNOLOGY CORP., LTD. – Smart Factory Project

All three projects passed provincial-level public announcements, serving as exemplary cases for industrial digitalization and intelligent factory development.

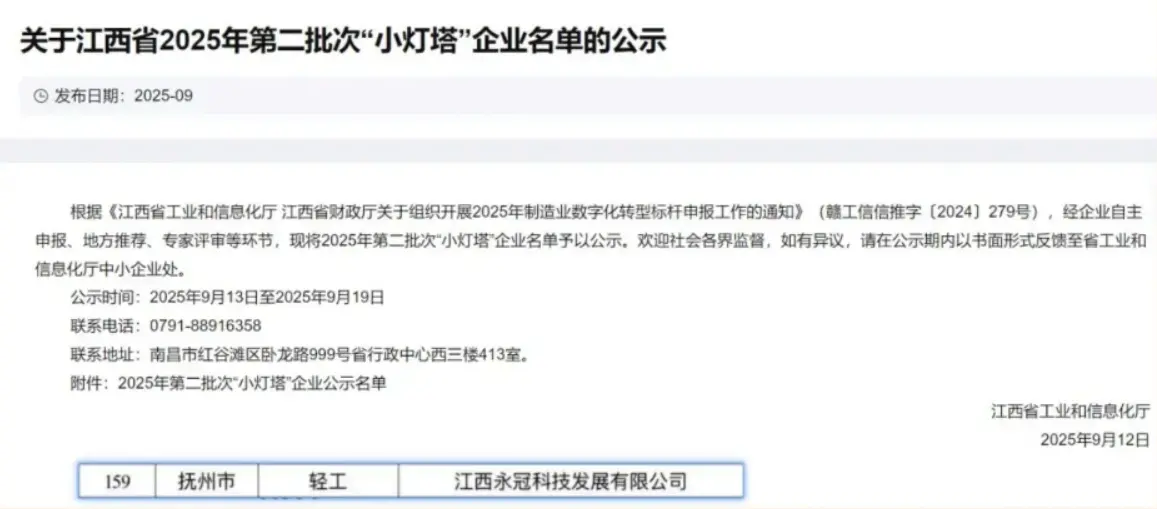

In addition, under the active leadership of Mr. Jiang Haiquan, Yongguan Technology was officially recognized as a Provincial Digital Transformation Pilot Benchmark Enterprise, highlighting YG Group’s comprehensive strengths in digital governance, system integration, and innovation execution.

Policy Incentives Empower Sustainable Digital Investment

Government incentives are a critical enabler of YG Group’s digital transformation journey. Rather than viewing subsidies as short-term financial gains, the company treats them as strategic resources to support long-term capability building.

Funds have been reinvested into:

-

Digital infrastructure upgrades

-

Enterprise data platforms

-

Intelligent production systems

-

AI-driven analytics and optimization

-

Digital talent development

This closed-loop mechanism—policy recognition, financial support, technological advancement, and competitiveness enhancement—has become a core driver of YG Group’s sustainable growth and aligns with national goals for manufacturing digital upgrades.

PLM-Centered Digital Upgrade and AI Integration

At the technical level, YG Group continues to advance digital depth through the comprehensive upgrade of its PLM (Product Lifecycle Management) system, forming a solid foundation for intelligent manufacturing.

By leveraging PLM system digitalization, the company enables:

-

End-to-end data integration across the product lifecycle

-

Intelligent analysis of production formulations

-

AI-assisted product performance prediction

-

Fine-grained process optimization and quality control

These capabilities accelerate the transition from traditional digitalization toward AI-driven manufacturing intelligence, improving efficiency, consistency, and innovation speed.

Future Outlook: Advancing Toward Intelligent, Data-Driven Manufacturing

Digital transformation will remain a long-term core strategy for YG Group. Moving forward, the IT Department will continue to lead cross-functional collaboration while expanding engagement with high-value policy programs.

Key focus areas include:

-

Provincial Data Enterprise Typical Case programs

-

National Digital Transformation Typical Case initiatives

-

MIIT AI “Unveiling & Task-Based Innovation” projects

Through deeper integration of data, AI, and industrial systems, YG Group will further enhance its intelligent manufacturing capabilities, driving refined operations and sustainable competitiveness.

Conclusion: Digital Intelligence Driving High-Quality Development

Through strategic leadership, systematic execution, and continuous technological innovation, YG Group has expanded both the depth and breadth of its digital transformation. Each certification, benchmark project, and policy recognition reflects a strong commitment to intelligent manufacturing and high-quality development.

By empowering businesses with technology and fueling growth with digital intelligence, YG Group continues to build a resilient, future-ready manufacturing ecosystem aligned with national strategy and global industrial trends.