YG Group Officially Recognized with CNAS Accredited Lab Status

YG Group Achieves CNAS Accreditation: Strengthening Global Trust in Adhesive Testing, Quality Assurance, and Material Innovation

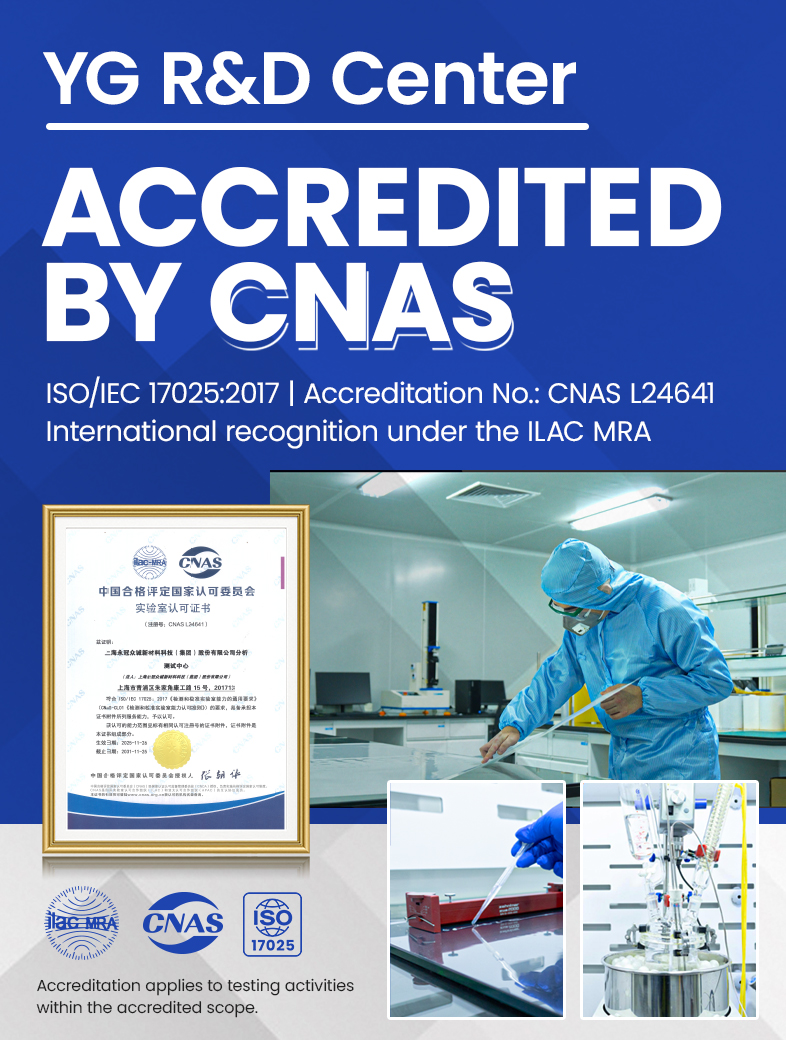

YG Group has reached a major milestone in its pursuit of scientific excellence and global leadership in adhesive and new material technologies. The company’s Analysis & Testing Center has officially passed the rigorous assessment of the China National Accreditation Service for Conformity Assessment (CNAS) and has been awarded the CNAS Accredited Laboratory qualification.

This accreditation covers multiple core testing categories, including physical performance testing, chemical performance analysis, accelerated weathering, adhesive behavior evaluation, and many other critical pillars essential to the adhesive, tape, label, film, and specialty material industries.

Because CNAS operates under the ILAC MRA (International Laboratory Accreditation Cooperation – Mutual Recognition Arrangement), YG Group’s accredited laboratory reports now carry global mutual recognition, meaning testing data and conclusions are accepted in numerous countries and regions worldwide.

This achievement places YG Group among the industry’s highly respected international testing laboratories and marks a new era of global competitiveness for the company.

What CNAS Accreditation Means and Why It Matters

CNAS is China’s nationally authorized accreditation body, established under law to evaluate and accredit laboratories, inspection bodies, and certification organizations. Its assessment framework is aligned with the globally recognized standard ISO/IEC 17025:2017, which is the highest benchmark for laboratory competence, impartiality, and consistent operation.

For a laboratory to earn CNAS accreditation, it must meet stringent requirements in:

-

Technical competence

-

Testing methodology standardization

-

Staff qualification and training

-

Equipment calibration and traceability

-

Quality management frameworks

-

Record integrity and auditability

-

Environmental and operational control

Only laboratories that demonstrate end-to-end compliance with these criteria are granted the CNAS mark—a quality seal that holds international credibility.

Why CNAS matters specifically for the adhesives and materials industry

In the adhesive industry, precision in testing is not optional—it is essential. Even minor discrepancies in coating thickness, adhesive formulation, polymer structure, or environmental exposure can significantly impact:

- Bonding strength

- Durability

- Temperature resistance

- Weather resistance

- Chemical compatibility

- Safety and reliability

CNAS accreditation confirms that YG Group’s testing data is scientifically robust, globally recognized, and reliable for customers in the automotive, packaging, label, decor, advertising, hardware, home & office, hot melt, and protection sectors.

A Milestone That Reflects YG Group’s Scientific Strength

YG Group’s successful accreditation highlights the organization’s long-term investment in research, engineering, and quality systems. With more than 100 R&D experts covering every discipline of adhesives, functional films, and specialty paper, YG Group operates one of the most comprehensive innovation ecosystems in the adhesive materials field.

YG Group’s Core Technology Capabilities

YG Group’s R&D capabilities span across several critical technological fields:

1. Coating Process Technology

Precision coating is fundamental to consistent adhesive and film quality. YG Group’s team specializes in:

-

Uniform coating weight control

-

Multi-layer coating technologies

-

Drying and curing optimization

-

Advanced tension and registration systems

-

High-speed industrial coating precision

2. PVC Substrate Engineering

Used widely in automotive wraps, protective films, and adhesive tapes, YG Group’s expertise ensures:

-

Dimensional stability

-

Flexibility and tensile balance

-

High weatherability

-

UV and heat resistance

3. Specialty Paper Development

YG Group formulates and produces specialty paper substrates, including:

-

Reinforced paper

-

Release base materials

-

Paper for labels and packaging logistics

4. Functional Film Innovation

The company develops and manufactures advanced functional films such as :

-

PET films

-

BOPP films

-

PE films

-

High-clarity films for packaging and labeling

-

Specialty films for protective and industrial applications

5. Rubber-based Adhesives

Used in packaging tape, masking tape, and duct tape, these adhesives require strong tack, peel adhesion, and shear resistance.

6. Hot-Melt Adhesives (EVA / PUR)

YG Group’s hot-melt systems are engineered for:

-

Strong bonding

-

Chemical resistance

-

Heat durability

-

Lamination and converting applications

7. Acrylic Adhesives (Water-based / Solvent-based)

Designed for environmental safety and high performance:

-

Clear and transparent bonding

-

High weather resistance

-

Stable adhesion across surfaces

-

Low VOC options

8. Water-Activated Adhesive Technologies

These eco-friendly adhesives power Kraft paper tapes used in packaging, e-commerce logistics, and heavy-duty sealing.

Together, these platforms position YG Group as a global leader in adhesive science and innovation.

A Fully Equipped CNAS-Accredited Laboratory: Precision in Every Stage of Testing

YG Group’s Analysis & Testing Center is equipped with a comprehensive range of advanced testing instruments that enable high-accuracy evaluation of adhesive performance, substrate behavior, aging, molecular analysis, and environmental resistance.

Below is an in-depth overview of the laboratory’s main equipment:

1. Physical & Mechanical Performance Testing

Voltage Breakdown Tester

Used to measure dielectric strength, especially important for electrical insulation tapes and materials used in power, electronics, and automotive wiring applications.

High and Low Temperature Testing Machine

Simulates extreme conditions from sub-zero temperatures to high-heat environments. It evaluates:

-

Adhesive durability

-

Physical stability

-

Temperature cycling performance

Essential for automotive, outdoor, and cold-chain logistics applications.

Ultraviolet Accelerated Weathering Tester

Simulates long-term UV exposure to test:

-

Aging behavior

-

Color stability

-

Adhesive degradation

-

Surface changes

This is critical for films and tapes used outdoors.

Initial Tack Tester

Measures quick-bonding performance—important for:

-

Carton sealing

-

Fast-paced packaging lines

-

High-speed label application

Constant Temperature and Humidity Chamber

Provides controlled environments for:

-

Aging tests

-

Dimensional stability analysis

-

Adhesive migration behavior

High-Temperature Retention Tester

Evaluates adhesion stability under sustained high-temperature loads, crucial for:

-

High-performance industrial tapes

Dynamic Shear Tester & Holding Power Test System

Ensures adhesives maintain strength under:

-

Static loads

-

Dynamic stress

-

Long-term usage conditions

2. Advanced Chemical and Molecular Analysis Equipment

Rotational Rheometer

Analyzes adhesive viscosity, viscoelastic behavior, and flow characteristics—key for coating uniformity.

Laser Diffraction Particle Size Analyzer

Determines particle size distribution in adhesive emulsions, affecting:

-

Stability

-

Optical clarity

-

Bonding consistency

Contact Angle Goniometer

Measures surface energy and wettability to confirm substrate–adhesive compatibility.

Fourier Transform Infrared Spectrometer (FTIR)

Used for molecular fingerprinting to analyze:

-

Chemical composition

-

Polymer structure

-

Curing state

-

Contaminants

Differential Scanning Calorimeter (DSC)

Evaluates thermal transitions such as:

-

Glass transition temperature (Tg)

-

Melting points

-

Thermal stability

-

Adhesive curing behavior

Gel Permeation Chromatograph (GPC)

Measures molecular weight distribution—one of the most important factors affecting adhesive performance and consistency.

International Recognition Through ILAC MRA

Because CNAS operates under the ILAC Mutual Recognition Arrangement, YG Group’s accredited test reports carry the equivalent authority of laboratories accredited in Europe, the United States, Canada, Australia, the Middle East, Latin America, and more.

This global recognition means:

-

No repeated testing when exporting

-

Faster approval by international customers

-

Smoother customs and compliance processes

-

Higher confidence in data authenticity

-

More credibility in OEM/ODM and technical partnerships

YG Group’s laboratory now functions as a globally trusted testing body, strengthening the company’s position in worldwide supply chains.

What This Accreditation Means for YG Group’s Customers

1. Stronger Quality Assurance Across All Production Sites

YG Group operates major manufacturing bases in:

CNAS certification enhances quality alignment and reinforces consistent global standards.

2. Faster New Product Development

With accredited testing, customers benefit from:

-

Accelerated validation

-

Data-driven formulation adjustments

-

Benchmark comparisons

-

Reliable analytical insights

This shortens the development cycle for both custom and standard products.

3. Transparent, Traceable, High-Integrity Data

Every CNAS-recognized test ensures:

-

Validated test methods

-

Fully traceable calibration records

-

Qualified technical personnel

-

Continuous audit compliance

4. Higher Reliability for Global Supply Chains

International customers gain confidence in:

-

Adhesive performance consistency

-

Safety and compliance

-

Environmental resistance

-

Product durability

This reliability is essential for industries with strict quality requirements, such as automotive, electronics, construction, and medical packaging.

Driving Sustainable Innovation for the Future

YG Group views CNAS accreditation not as a final achievement, but as the foundation for long-term innovation and global excellence.

The company will continue to invest in:

-

Eco-friendly adhesive systems

-

Water-based and solvent-free technologies

-

Smart labeling materials

-

High-performance industrial tapes

-

Automotive protective films

-

Functional packaging solutions

-

Sustainable raw material development

With advanced testing and strong R&D capabilities, YG Group is accelerating the transformation of high-performance materials for global industries.

Conclusion

The CNAS accreditation of YG Group’s Analysis & Testing Center marks a significant leap forward in global testing capability, technical authority, and international recognition. It demonstrates the company’s unwavering commitment to:

-

Scientific rigor

-

Quality excellence

-

Global compliance

-

Customer-driven innovation

-

Sustainable material development

With globally recognized laboratory data, a world-class R&D team, and advanced testing infrastructure, YG Group is well-positioned to serve as a leading partner in the global adhesives, tapes, labels, films, and specialty materials industries.

YG Group’s laboratory now stands among internationally recognized testing institutions—offering customers around the world a trusted, authoritative, and forward-looking foundation for innovation and quality assurance.