Transfer Tape for Vinyl: A Practical Guide to Modern Transfer Film Solutions

Transfer tape is a key tool in vinyl application. It connects cutting, positioning, and final placement into one smooth process. Without it, vinyl graphics become hard to handle and easy to damage.

As vinyl is widely used in signage, packaging, decoration, and branding, transfer tape must evolve. Today, users need more options, not one fixed solution.

For this reason, our company has launched a new adhesive transfer tape series. It includes washi paper transfer tape, PET transfer tape, and OPP transfer tape. In addition, we offer low-tack and linerless options to match different workflows.

This article explains how transfer tape works, how materials differ, and how to choose the best transfer tape for vinyl based on real application needs.

What Is Transfer Tape?

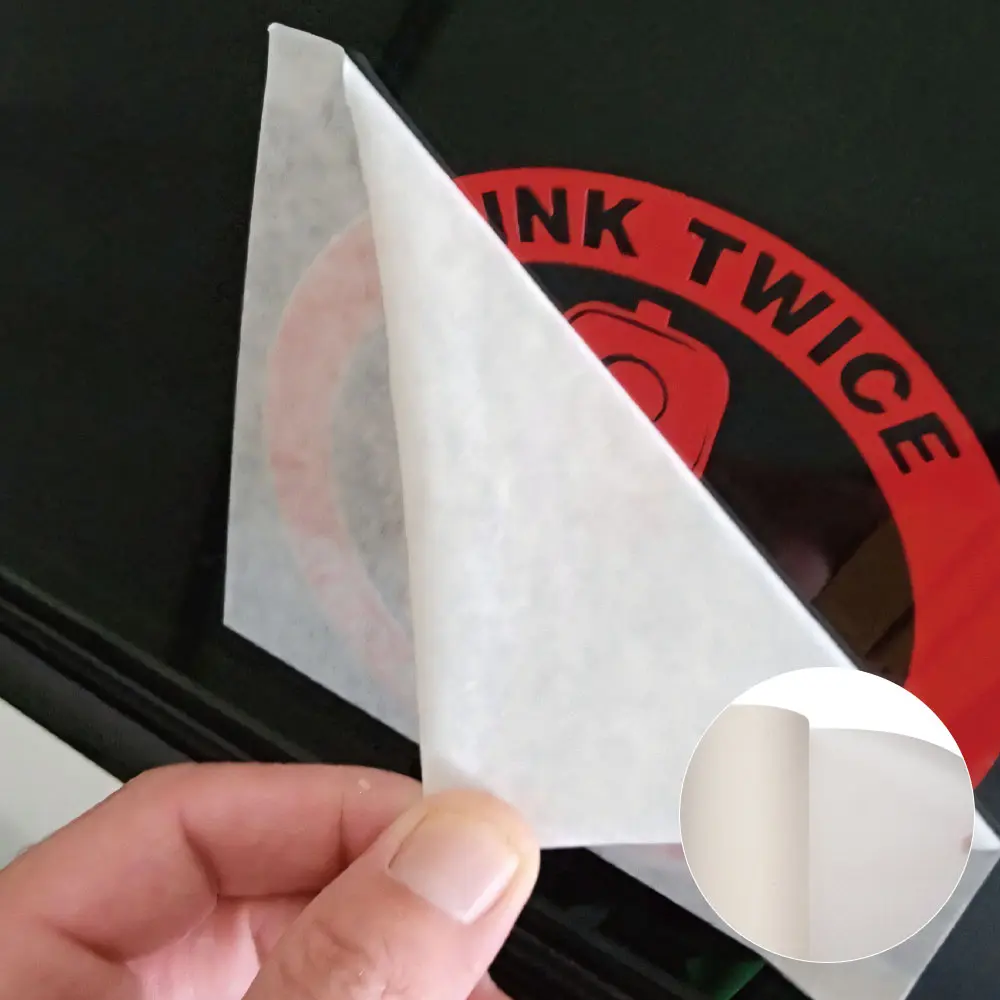

Transfer tape is a temporary adhesive layer. It moves vinyl graphics from the release liner to the target surface. After placement, the tape is removed, while the vinyl stays.

Unlike permanent adhesive tapes, transfer tape must balance grip and release. It must hold vinyl firmly. However, it must also peel away cleanly.

Because of this balance, material choice matters. Different backings and adhesives create different performance levels. Therefore, users should not treat all transfer tapes the same.

How Transfer Tape for Vinyl Works

Vinyl graphics often include small details. Letters and thin lines can shift easily. Transfer tape keeps all parts aligned.

First, the tape is applied to the vinyl surface. Then, the liner is removed. Next, the vinyl is placed on the substrate. Finally, the tape peels off.

Each step depends on adhesive control. If tack is too high, vinyl lifts. If tack is too low, vinyl drops. Therefore, stable adhesive behavior is essential.

Main Types of Transfer Tape by Material

Washi Paper Transfer Tape

Washi paper transfer tape uses a soft, fiber-based paper backing. It offers good flexibility and easy handling.

Because washi paper breathes well, air escapes more easily during application. This reduces bubbles. As a result, it works well for wall decals and flat surfaces.

In addition, washi paper tears easily by hand. This improves efficiency in manual work. Therefore, many installers prefer it for daily use.

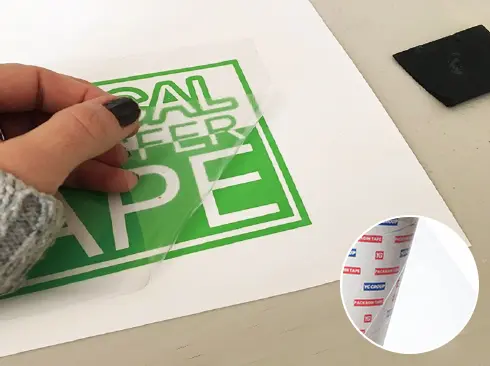

PET Transfer Tape

PET transfer tape uses a polyester film backing. It is clear and dimensionally stable.

Because PET is transparent, alignment becomes easier. Users can see the graphic and surface clearly. This helps with precise placement.

PET backing also resists stretching. Therefore, it performs well in detailed graphics and repeated applications.

OPP Transfer Tape

OPP transfer tape uses oriented polypropylene film. It offers a balance between flexibility and strength.

Compared with PET, OPP is softer. At the same time, it keeps good clarity. This makes it suitable for medium-detail graphics.

OPP transfer tape also unwinds smoothly. As a result, it supports faster application in production environments.

Low-Tack Transfer Tape for Sensitive Vinyl

Some vinyl films have soft surfaces. Others use weak adhesive systems. In these cases, standard tack may be too strong.

For this reason, we offer low-tack transfer tape options. They reduce pull force during removal. However, they still keep enough grip during placement.

Low-tack tape helps prevent edge lifting. It also protects delicate vinyl finishes. Therefore, it suits matte and specialty vinyl films.

Linerless Transfer Tape: Improving Efficiency

Traditional transfer tape uses a release liner. However, liners create waste. They also slow down workflow.

Our linerless transfer tape removes the liner layer. This reduces material waste. At the same time, roll length increases.

Because there is no liner to remove, application becomes faster. Storage also becomes more efficient. Therefore, linerless tape suits high-volume users.

What Makes the Best Transfer Tape for Vinyl?

There is no single answer. However, good transfer tape shares common traits.

First, adhesive strength must be controlled. It must lift vinyl cleanly. Yet, it must release smoothly.

Second, the backing must stay flat. Curling or stretching causes alignment errors.

Third, performance must stay consistent. Every roll should behave the same. This reduces mistakes and waste.

Our adhesive transfer tape series was designed with these principles in mind.

Adhesive System: The Core of Transfer Tape

Adhesive defines performance. Even small changes affect results.

Our transfer tape uses pressure-sensitive adhesive. It maintains stable tack across temperature changes. It also resists aging during storage.

Because adhesive stays consistent, users get predictable behavior. As a result, production becomes easier to control.

You can learn more about adhesive fundamentals in pressure sensitive adhesive tape technology.

Applications of Vinyl Transfer Tape

Transfer tape supports many industries. It is not limited to signage.

Common applications include:

-

Vinyl decals and stickers

-

Wall graphics and home decoration

-

Packaging labels

-

Promotional graphics

-

Automotive lettering

As vinyl usage grows, transfer tape demand also increases. Therefore, product variety becomes more important.

Our Adhesive Transfer Tape Product Range

Our new product range includes:

-

Washi paper transfer tape

-

PET transfer tape

-

OPP transfer tape

-

Low-tack options

-

Linerless transfer tape

Each type is designed for different needs. This allows users to choose based on workflow and vinyl type.

You can view the full range on our transfer tape product page.

Performance on Different Vinyl Films

Vinyl films differ in thickness and surface energy. Therefore, transfer tape must adapt.

Our tapes work well with:

-

Glossy vinyl

-

Matte vinyl

-

Printable vinyl

-

Colored cutting vinyl

Because adhesive strength is controlled, lifting remains clean. At the same time, release stays smooth.

Ease of Use in Real Workflows

Transfer tape should simplify work, not complicate it.

Our tapes apply with light pressure. They also peel cleanly at different angles. Because of this, both beginners and professionals can use them easily.

In addition, roll edges stay neat. This improves handling during cutting and storage.

Manufacturing Control and Quality Stability

Transfer tape quality depends on manufacturing control.

We manage:

-

Adhesive coating weight

-

Backing thickness tolerance

-

Roll flatness

-

Batch consistency

These controls help ensure stable performance. You can explore our capabilities through industrial adhesive tape manufacturing.

Choosing the Right Transfer Tape

Before selecting transfer tape, consider:

-

Vinyl surface type

-

Graphic size

-

Alignment needs

-

Production volume

For clear positioning, PET or OPP works well. For bubble control, washi paper is effective. For efficiency, linerless tape is ideal.

If customization is needed, our OEM adhesive tape solutions can support private label projects.

Final Thoughts on Transfer Tape for Vinyl

Transfer tape may seem simple. However, it strongly affects final results.

The best transfer tape for vinyl balances hold, release, and stability. It must match the vinyl and workflow.

Our new adhesive transfer tape series provides flexible options. With multiple materials and adhesive levels, it supports modern vinyl applications.

For brands and installers seeking reliable transfer solutions, this product line offers a solid and scalable choice.