UV Digital Inkjet Label: Fast, Durable & High-Quality Labels for Modern Printing

UV digital inkjet label is a smart choice for modern brands that need fast printing and strong visual impact. It supports sharp text, vivid colors, and stable QR codes or barcodes. As more packaging moves to short runs and variable data, UV inkjet printing helps businesses stay flexible.

At YG Group, we launch our new UV digital inkjet label solution for retail packaging, logistics identification, and product labeling. These labels are designed for high-speed digital printing with reliable surface performance and consistent results. In this guide, you will learn key benefits, best uses, and how to choose the right label material for your market.

What Is a UV Digital Inkjet Label?

A UV digital inkjet label is a pressure-sensitive label designed for UV inkjet printing systems. It uses UV-curable ink and UV light to create fast-drying, high-resolution prints.

Unlike traditional printing, UV inkjet printing does not rely on long drying time. Instead, the ink is cured instantly. This makes the printing process faster and cleaner.

In simple words:

-

Ink is printed onto the label surface

-

UV light cures the ink immediately

-

The print becomes dry, strong, and stable

As a result, UV digital inkjet labels are great for:

-

Variable data printing (QR codes, serial numbers, barcodes)

-

Short runs and customized designs

-

Fast delivery and flexible production

This is why many modern print shops, packaging companies, and brand owners are shifting to UV digital label printing.

Why UV Digital Inkjet Printing Is Growing So Fast

Many brands are upgrading from traditional printing methods. The main reasons are easy to understand.

1) Brands Need Faster Time-to-Market

Product launches are more frequent today. Because of this, labels also change faster. UV inkjet printing supports quick updates without waiting for plates or long setup.

2) Short Runs Are More Common

Many businesses produce more SKUs than before. Some products need only small label quantities. UV digital printing supports short runs at a stable speed.

3) Variable Data Is a Big Requirement

QR codes, tracking numbers, and smart packaging are everywhere. UV inkjet printing can add unique information on every single label.

4) Quality Expectations Are Higher

Modern customers want premium packaging. They notice details like sharp text, deep black, and fine gradients. UV inkjet labels provide strong print results, even in small sizes.

So, UV digital printing is not just a trend. It is becoming the standard for many label markets.

How UV Digital Inkjet Printing Works (Simple Explanation)

UV digital inkjet printing uses UV-curable inks. These inks stay liquid until UV light hits them. Then, they become solid within seconds.

Here is the simple process:

-

Inkjet head sprays ink onto the label surface

-

UV lamp cures the ink instantly

-

The label comes out dry and ready

-

No waiting time, no smudging

Because the ink is cured quickly, the result is more stable. The label can resist rubbing and handling better than many standard digital prints.

Also, UV printing can work well on more label surfaces, including some film materials.

Key Benefits of UV Digital Inkjet Labels

A good label does more than “look nice”. It must perform well in real-life use. This includes printing, converting, shipping, and daily application.

Here are the main advantages of UV digital inkjet labels.

Fast Drying, Faster Production

UV curing is instant. Therefore, you can print and finish labels faster.

This helps when you have:

-

urgent orders

-

short delivery time

-

high SKU changes

Also, it supports higher printing efficiency without quality loss.

High Resolution and Strong Visual Impact

UV inkjet printing produces sharp details. Even small text can be clear.

So it is ideal for:

-

QR codes

-

fine lines

-

small barcodes

-

premium designs

This helps brands build a better product image on the shelf.

Better Smudge and Scratch Resistance

Because UV ink is cured, it creates a stronger print layer.

This is important when labels are:

-

handled many times

-

shipped long distance

-

stored in warehouses

-

applied on products with friction

For B2B buyers, this reduces complaints and rework.

Suitable for Variable Information Printing

UV inkjet labels can print unique data on each label, such as:

-

batch number

-

serial number

-

shipping code

-

ingredient updates

-

anti-counterfeit QR code

Because of this, UV digital labels work well for smart packaging needs.

Supports Custom Orders and Flexible Design

Many customers want small quantity customization. For example:

-

seasonal labels

-

limited edition packaging

-

event campaigns

-

personalized products

UV digital printing makes these jobs easier and faster.

Common Applications of UV Digital Inkjet Labels

UV digital inkjet labels are used in many industries. This is because they offer both quality and flexibility.

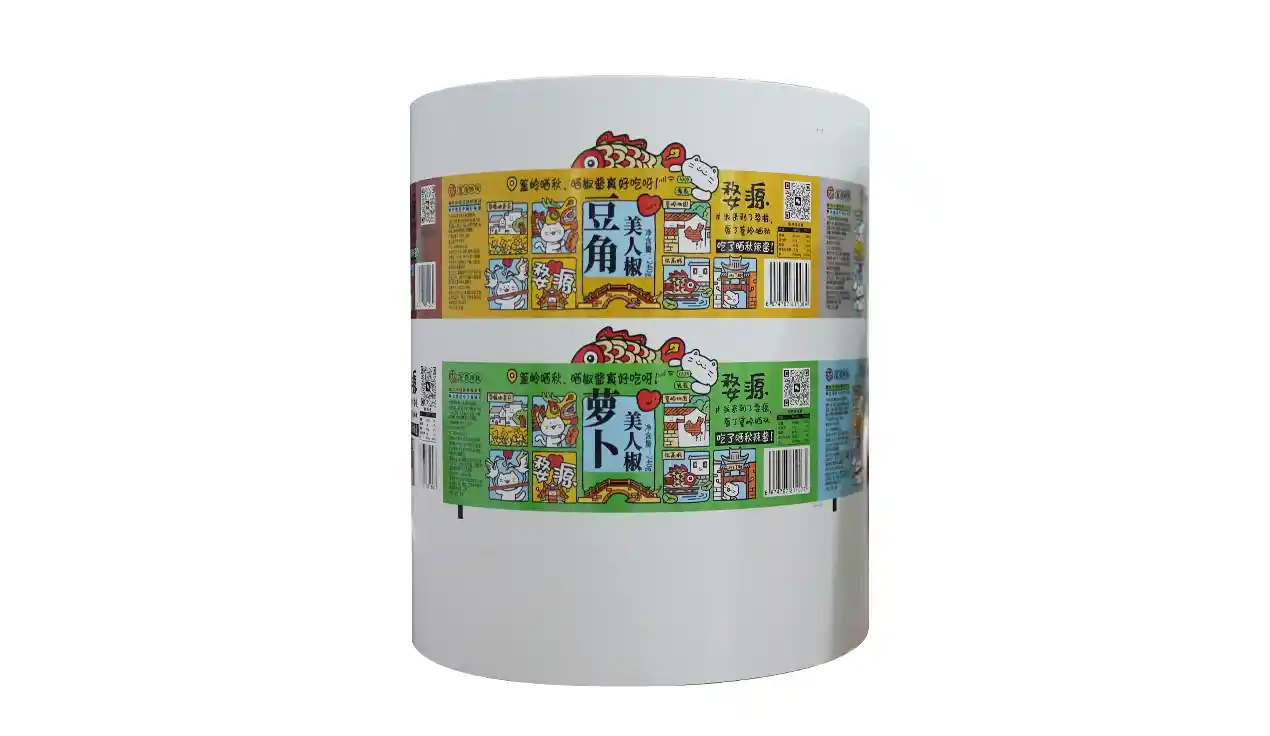

Food and Beverage Labels

Food packaging must look clean and professional. At the same time, product information changes often.

UV digital labels help with:

-

nutrition updates

-

multi-language packaging

-

promotional designs

-

barcodes and traceability

Because prints are sharp, product details stay easy to read.

Daily Chemicals and Personal Care

Cosmetic and cleaning products often use strong branding. Labels must show fine design and color accuracy.

UV digital inkjet labels work well for:

-

shampoo bottles

-

hand soap labels

-

skincare products

-

household chemical packaging

Also, the print is more stable for daily handling.

Logistics and Variable Data Labels

Many logistics labels need high-speed printing and high scan rates.

UV digital printing supports:

-

crisp barcodes

-

clear QR codes

-

fast production

-

stable black density

If your business needs label performance in shipping, this is a strong option.

You can also explore our Logistic Label solutions for shipping and warehouse use.

Retail and Promotional Labels

Retail labels often change designs quickly. Promotions are also time-sensitive.

UV digital inkjet labels can support:

-

seasonal marketing

-

limited runs

-

price labels

-

product launch packaging

This gives brands more freedom to run campaigns.

Industrial Product Identification

Some industrial products require labels with stable text and codes for tracking.

UV digital printing is useful for:

-

tools and parts labeling

-

OEM packaging

-

warehouse ID labels

-

product tracking labels

It helps reduce reading errors and scanning issues.

UV Digital Inkjet Labels vs Traditional Label Printing

Many buyers ask: “Should we switch to UV digital?”

It depends on your business goals. However, here is a simple comparison.

Traditional Printing (Flexo / Offset)

Traditional printing is very good for:

-

large quantities

-

stable design

-

lower cost per unit at scale

But it usually needs:

-

printing plates

-

longer setup time

-

higher MOQ for efficiency

So, it may not be ideal for short runs.

UV Digital Inkjet Printing

UV digital printing is good for:

-

short runs

-

fast delivery

-

variable data

-

fast design changes

Also, it reduces setup complexity. This helps many modern buyers.

Therefore, many customers use both methods. They use traditional printing for big-volume jobs, and UV inkjet for flexible jobs.

How to Choose the Right UV Digital Inkjet Label Material

A label is not only about printing. The base material also matters.

When choosing a UV inkjet label, you should check:

1) Surface Compatibility

The label surface must accept UV ink well. If the surface is not compatible, the ink may not bond properly.

So, it is important to choose a UV inkjet-ready face stock.

2) Adhesive Performance

Adhesive is critical for real application.

A good adhesive should match:

-

product surface (plastic, metal, glass, paper)

-

use environment (cold, heat, moisture)

-

service time (short-term vs long-term)

If you need help choosing, YG Group can support adhesive matching.

3) Liner Type for Converting and Dispensing

The liner affects die cutting and label dispensing performance.

This is especially important for:

-

automatic labeling machines

-

high-speed printing lines

-

smooth peeling performance

A stable liner can reduce waste during processing.

4) End Use Environment

Ask yourself these questions:

-

Will the label face water or humidity?

-

Will it face heat or sunlight?

-

Will it be rubbed often during shipping?

For harsh conditions, film labels or durable materials may be better.

You can also review our Durable Film Label options for long-lasting performance.

What Makes a Good UV Digital Inkjet Label Supplier?

Choosing the right supplier is a key step for B2B buyers. Price is important, but stable quality is even more important.

Here are the main points to consider.

Stable Quality Control

A good supplier must have:

-

consistent coating performance

-

stable adhesive quality

-

controlled release force

-

repeatable printing results

This helps you reduce complaints and reorders.

Customization Ability

Many customers want:

-

custom width and length

-

custom adhesive level

-

custom packaging

-

OEM / ODM support

A professional supplier should support flexible needs.

Supply Chain and Delivery Support

For global buyers, supply security matters.

A reliable supplier should offer:

-

stable production planning

-

export support

-

international shipping experience

-

fast response communication

That is why many customers choose factory-direct partners.

Why Choose YG Group for UV Digital Inkjet Labels?

YG Group is a global manufacturer of adhesive products. We supply labels, tapes, films, and digital print materials for worldwide customers.

For UV digital inkjet labels, we offer:

-

factory-direct production

-

stable coating and adhesive technology

-

support for different application needs

-

customized sizes and specifications

-

global delivery support

If you need more digital print solutions, you can explore our complete Digital Printing Label category.

We also support other label materials for different markets, such as prime paper labels and functional labels.

Best Use Tips for UV Digital Inkjet Labels

To get better printing results, you can follow these easy tips:

Store Labels in a Stable Environment

For best performance:

-

keep labels in a dry place

-

avoid direct sunlight

-

store at stable room temperature

-

keep cartons sealed until use

This helps protect the surface and adhesive.

Run a Small Print Test First

Before mass production, test:

-

ink adhesion

-

barcode scan rate

-

scratch resistance

-

die-cut accuracy

This reduces risk and improves consistency.

Match Adhesive to Application Surface

Not all surfaces are the same. For example:

-

HDPE bottles need strong adhesive bonding

-

glass may need removable clean peel

-

cardboard packaging may need standard permanent

If you are unsure, YG Group can recommend a suitable option.

Conclusion: A Smarter Label Choice for Fast-Changing Markets

UV digital inkjet labels are a strong solution for modern packaging needs. They support speed, quality, and customization.

If your business needs:

-

fast delivery label production

-

stable print quality

-

clear codes and sharp designs

-

flexible order quantity

Then UV digital inkjet labels can help you move faster and compete better.

At YG Group, we support global B2B customers with reliable label materials and factory-direct service. From digital printing labels to durable film labels, we provide stable quality for real market use.